Technology

Paste filling coal mining method: the gangue is processed into a toothpaste slurry with "no critical flow rate and no dehydration", which is transported to the coal mining face through pipeline under the action of pump pressure or gravity, timely fills the goaf, realizes the control of rock stratum movement and ground subsidence, and liberates the "three down" coal pressure and the resource utilization of solid waste.

Classification of paste filling methods: it can be divided into cemented paste filling and non cemented paste filling according to whether cement (binder) is used or not; According to the mining and filling process of filling face, it is divided into fully mechanized mining paste filling and strip paste filling; According to the main filling materials, it is divided into gangue gypsum, fly ash paste and aeolian sand loess paste.

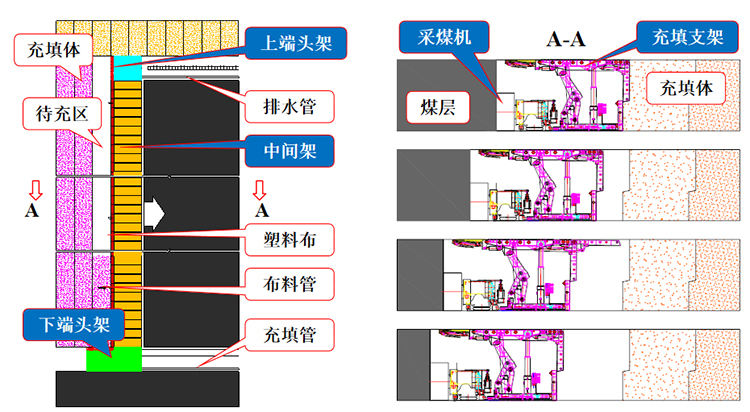

2.1 fully mechanized cemented paste filling coal mining

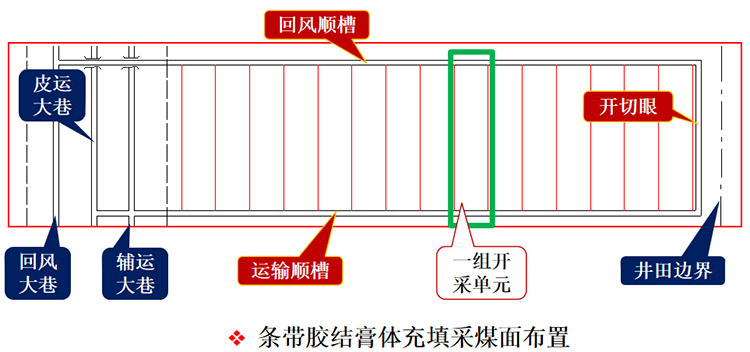

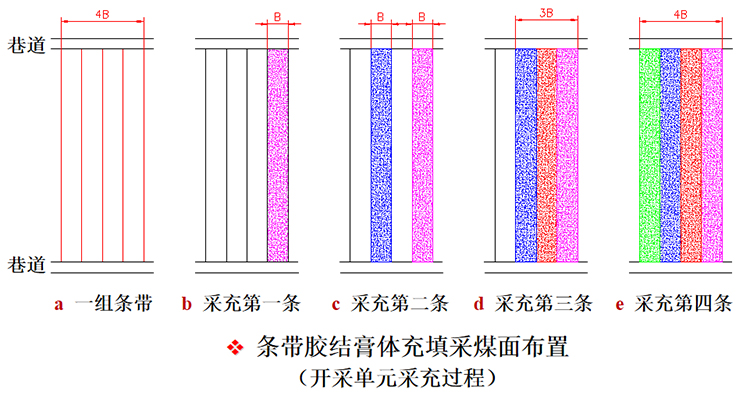

2.2 strip cemented paste filling coal mining

2.2 strip cemented paste filling coal mining

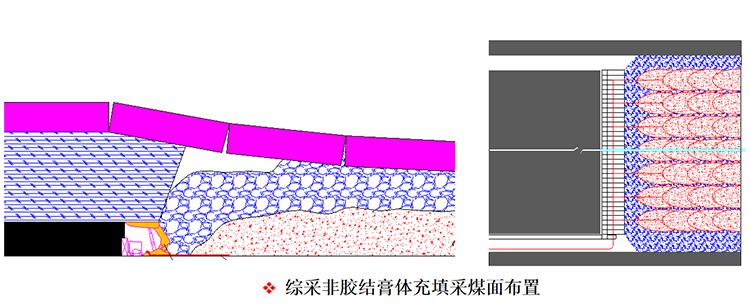

2.3 fully mechanized mining non cemented paste filling coal mining

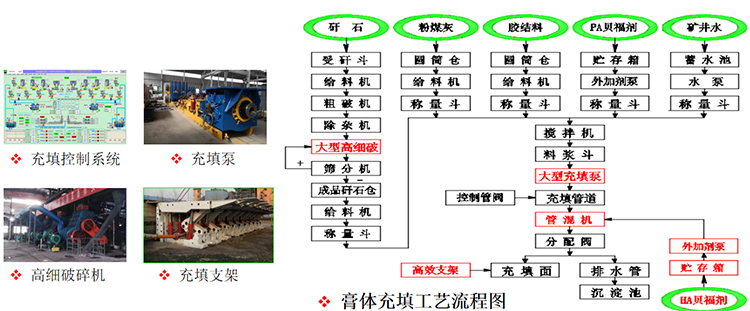

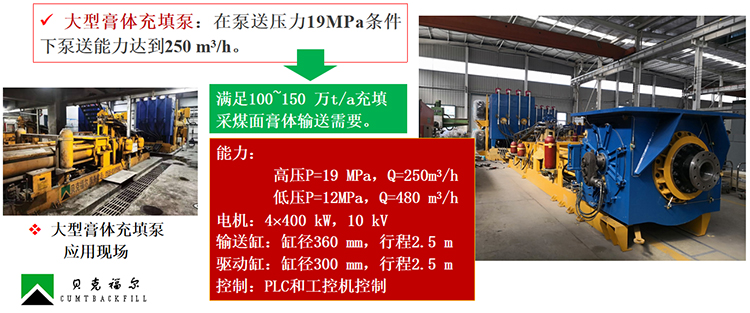

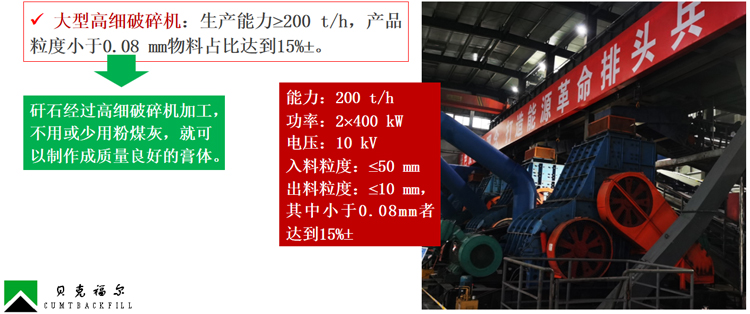

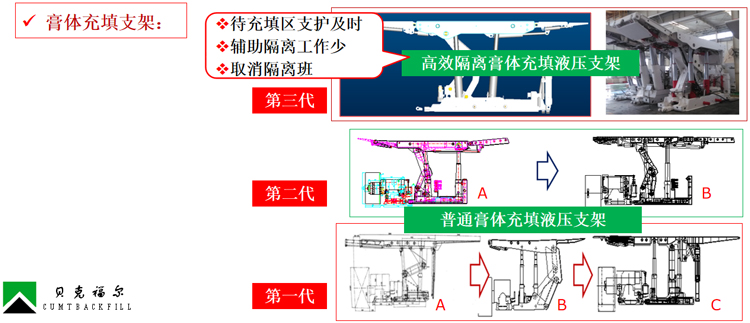

2.4 paste filling process and equipment

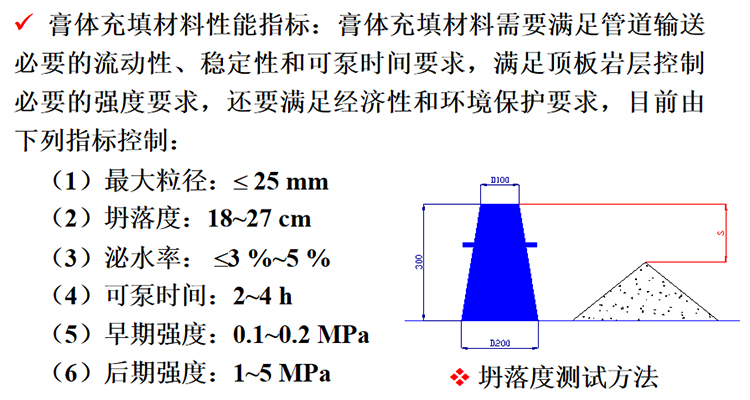

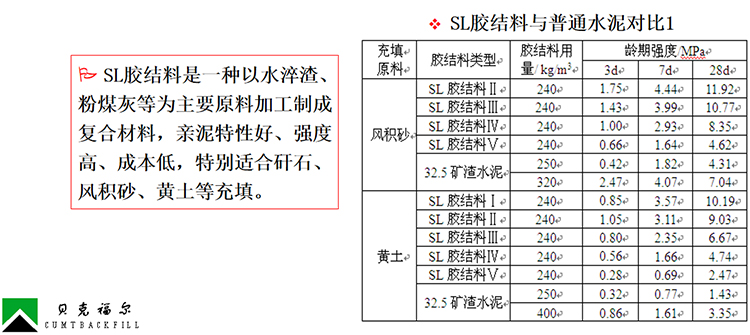

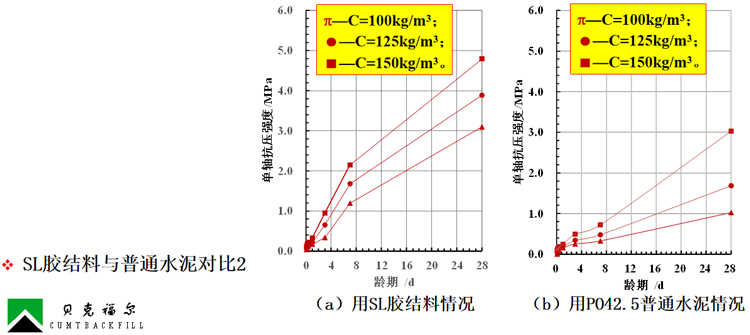

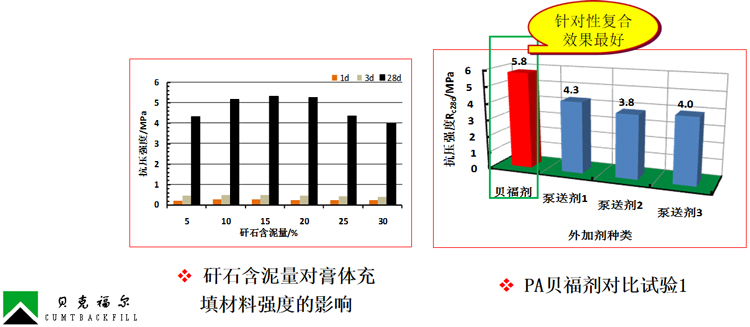

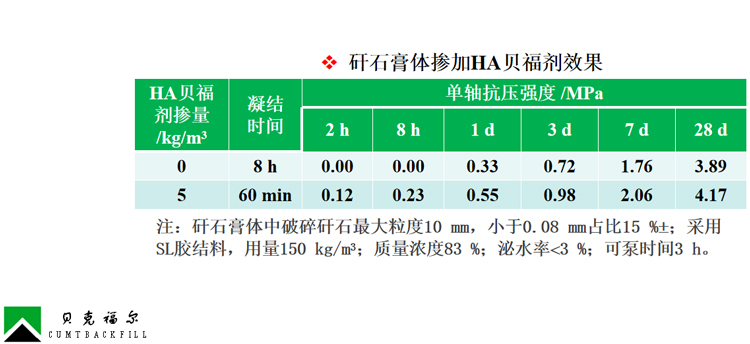

2.5 paste filling materials